Page 75 - 2025S

P. 75

68 UEC Int’l Mini-Conference No.54

Effect of tube dimension and material

on formability in eccentric tube

processing by expansion drawing

Phone Myint Aung, Shohei Kajikawa

Department of Mechanical Engineering and Intelligence Systems

University of Electro-Communications Tokyo, Japan

1.Introduction 4.Results

Tube drawing is widely used in manufacturing high-precision

tubular products for industries such as automotive, aerospace,

and energy.

Traditional tube drawing produces uniform tubes, but certain

applications require intentional dimensional asymmetry or

eccentricity.

Eccentric tube expansion drawing uses an eccentric plug to

deliberately shift material distribution, producing tubes with

variable wall thickness or inner contours.

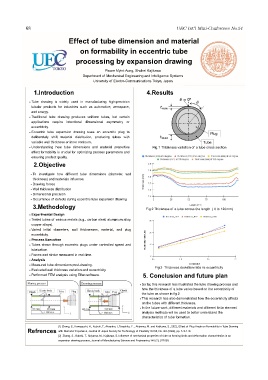

Understanding how tube dimensions and material properties Fig.1 Thickness variation of a tube cross section

affect formability is crucial for optimizing process parameters and

ensuring product quality.

2.Objective

To investigate how different tube dimensions (diameter, wall

thickness) and materials influence:

Drawing forces

Wall thickness distribution

Dimensional precision

Occurrence of defects during eccentric tube expansion drawing

3.Methodology Fig.2 Thickness of a tube across the length ( 0 to 120mm)

Experimental Design

Tested tubes of various metals (e.g., carbon steel, aluminium alloy,

copper alloys).

Varied initial diameters, wall thicknesses, material, and plug

eccentricity.

Process Execution

Tubes drawn through eccentric plugs under controlled speed and

lubrication.

Forces and stroke measured in real-time.

Analysis

Measured tube dimensions post-drawing.

Fig.3 Thickness deviation ratio vs eccentricity

Evaluated wall thickness variation and eccentricity.

Performed FEM analysis using Elfen software. 5. Conclusion and future plan

So far, this research has illustrated the tube drawing process and

how the thickness of a tube varies based on the eccentricity of

the tube as shown in fig.2

This research has also demonstrated how the eccentricity affects

on the tubes with different thickness.

In the future work, different materials and different finite element

analysis methods will be used to better understand the

characteristics of tube formation.

[1] Zhang, S., Kawaguchi, H., Kuboki, T., Akasaka, I.,Terashita, Y ., Akiyama, M. and Kajikawa, S., 2022, Effect of Plug Angle on Formability in Tube Drawing

Refrences with Diameter Expansion, Journal of Japan Society for Technology of Plasticity Vol 68, No.748 (2022), pp. 174-179.

[2] Zhang, S., Kuboki, T., Akiyama, M., Kajikawa, S, Influence of mechanical properties of tube on forming limits and deformation characteristics in an

expansion drawing process, Journal of Manufacturing Science and Engineering 146 (7), 071005